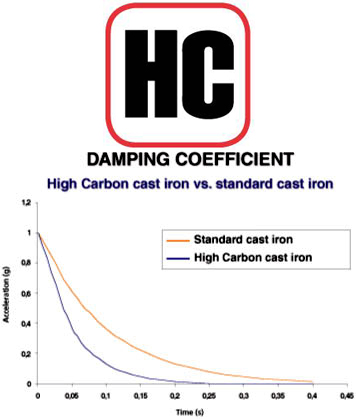

High carbon cast iron discs

Discs with HC coding are produced using special cast iron with a high carbon content that guarantees better performance and less risk of noises compared to normal cast iron thanks to a better damping factor.

TÜV / ABE certification

Brembo has obtained ABE homologation for its whole range of brake discs. This is issued by the German Federal Authority for Road Transport on the certification of TÜV of Munich. This is possible because Brembo directly develops and produces the whole range of its brake discs in its own factories with very high quality standards ensured by stringent checks on the whole production process.

Fixing screw kit

Since the fixing screws could be damaged when a used disc is removed, a kit with two new screws is provided in each pack of Brembo discs marked with the special yellow label. This will ensure that the work is done more quickly and safely and will be technically perfect.

Discs with built-in bearing kit

No more replacement problems:

bearings are factory preassembled and discs ready for immediate installation, which means big savings in time and effort. Discs may also come with integral ASB® sensor, depending on the OE specification.

OE supplier

Brembo is the largest European manufacturer of OE brake discs and original spares, and offers the largest overall range of original brake discs.

Pillar venting technology

The innovative Brembo patented pillar venting technology boosts overall disc cooling and increases up to more than 40% resistance to thermal cracking.

Anti-corrosion painting

Dedicated to those users who also place importance on aesthetic considerations. Brembo has painted the sections not subject to the braking actions. This feature is available only for high range vehicles and will be appreciated by those who have alloy wheels.

REPLACEMENT INSTRUCTIONS

DANGER! Before proceeding with replacement, make certain that the replacement part is suitable for the make and model of vehicle.

DANGER! This Product is of vital importance for the safe operation for the vehicle on which it is installed, and must therefore be fitted only by a skilled mechanic who has been properly trained or achieved a suitable level of experience in the installation and use for which the Product is intended. The installer must be in possession of the right tools and equipment for the job, and sufficiently knowledgeable and expert as a mechanic to perform servicing on the vehicle. Improper or incorrect installation, occurring through failure to abide by the Instructions, or other causes, will invalidate the Limited Warranty and the installer could become liable for damages caused to persons or property. BREMBO declines liability for any damage or injury caused to or by any person driving a vehicle on which a replacement product has been incorrectly installed.

DANGER! Replace both the brake discs on each axle, taking them from the same pack. Whenever discs are changed, renew the relative pads as well.

WARNING! Dispose of replaced parts in accordance with statutory regulations.

WARNING! Avoid striking hard and/or inflicting damage on the Product and its component parts, as this could impair their efficiency and cause them to malfunction. Replace damaged components when necessary.

WARNING! To avoid injury:

– Always wear gloves during the operations of removing and refitting components that present sharp edges.

– Avoid bringing the friction material of brake pads and shoes into direct contact with the skin, as it can cause abrasion.

DANGER! Avoid bringing grease and other lubricants into contact with the braking surfaces of the disc and pads, as this could render the brakes ineffective.

REPLACEMENT PROCEDURES

The procedure described is for one wheel, and must be repeated on the other wheel of the axle.

1. Remove the wheel.

2. Remove the pads from the caliper and retract the piston/s, using the special tool.

3. Remove the caliper from its mount.

DANGER! Do not disconnect the brake fluid line to the caliper. Suspend the caliper, ensuring that the pipeline is not pulled taut.

4. If necessary, remove the wheel hub before removing the disc. Remove the disc.

5. Clean the mounting face of the new disc.

CAUTION! Do not foul the mounting face with oil or grease.

6. Clean the mounting face of the wheel hub, removing any deposits and rust; check that the surface is not damaged or deformed, and restore it to the proper condition if necessary.

7. Check for smooth rotation and correct end float of the wheel bearings.

8. If the wheel hub has not been removed: fit the new disc to the wheel hub and secure with the fixing bolt; adjust the bearing when required, following the directions of the vehicle maker.

9. If the wheel hub was removed in Step 4: assemble the hub and disc, tightening the fixing bolts to the specified torque. Fit the assembled hub and disc to the axle, adjust the bearing and complete the operation as directed by the vehicle maker.

10. Check lateral runout of the disc using the metrological kit; the dial gauge must be positioned as illustrated, 5mm from the outer diameter. Secure the disc with a number of wheel nuts to simulate the condition in which the wheel is mounted. The maximum value of runout per full revolution of the dic is: 0.10mm for cars – 0.12mm for commercial vehicles. If necessary, remove the disc and refit to the wheel hub in a different position, then repeat the measurement.

CAUTION! Conduct this test with care. A runout value higher than indicated will lead to abnormal wear and generate vibration when braking.

11. If the runout measure is unacceptable, measure the runout of the wheel hub mounting face; if necessary, replace the hub and refit the disc.

CAUTION! The permissible runout value for the wheel hub mounting face is approximately half that specified for the disc.

12. Refit the caliper to its mount; in the case of a floating caliper, check for smooth sliding action of the pins and guides bushes.

WARNING! Check that rubber parts are not damaged. Replace if necessary.

13. Fit the new pads, with the relative springs and pins. Grease the back and edges of the pads where indicated. Connect the wear indicator, if installed.

14. Depress the brake pedal to squeeze the pads against the disc. Repeat the operation until the pedal travel is at it should be.

15. Check the level of brake fluid in the reservoir, topping up if necessary.

16. Refit the wheel and tighten the wheel nuts as indicated by the vehicle maker or as in the Brembo catalogue.

17. Balance the wheel.

TESTING AND RUNNING IN

Road test the vehicle, taking care not to stab at the brakes or keep the pedal depressed for more than 3 seconds; make certain there is no noise or vibration from the brakes. The user of the vehicle should run in the new discs and pads for at least 200km, applying the brakes gently and sparingly, and without activating the ABS.

WARNING! If new brakes are not properly run in, the braking system could be prevented from operating efficiently.